Particle size distribution is a critical parameter in various industries, influencing the performance and quality of products ranging from pharmaceuticals to paints and powders. Understanding particle size distribution is essential for optimizing processes, ensuring product consistency, and meeting regulatory requirements. The fundamentals, measurement techniques, and the significance of particle size distribution.

Fundamentals of Particle Size Distribution:

Particle size distribution refers to the range of particle sizes present in a sample. It is a key characteristic that impacts the behavior and properties of materials. Particles can vary in size from nanometers to millimeters, and their particle size distribution plays a vital role in determining the physical, chemical, and mechanical properties of a substance.

Measurement Techniques:

- Microscopy: Traditional microscopy methods involve visually analyzing particles under a microscope. While effective, this method is time-consuming and may not be suitable for large-scale analysis.

- Sieve Analysis: In this method, particles are separated based on size using a series of stacked sieves. While simple and widely used, it may not be suitable for nanoscale particles.

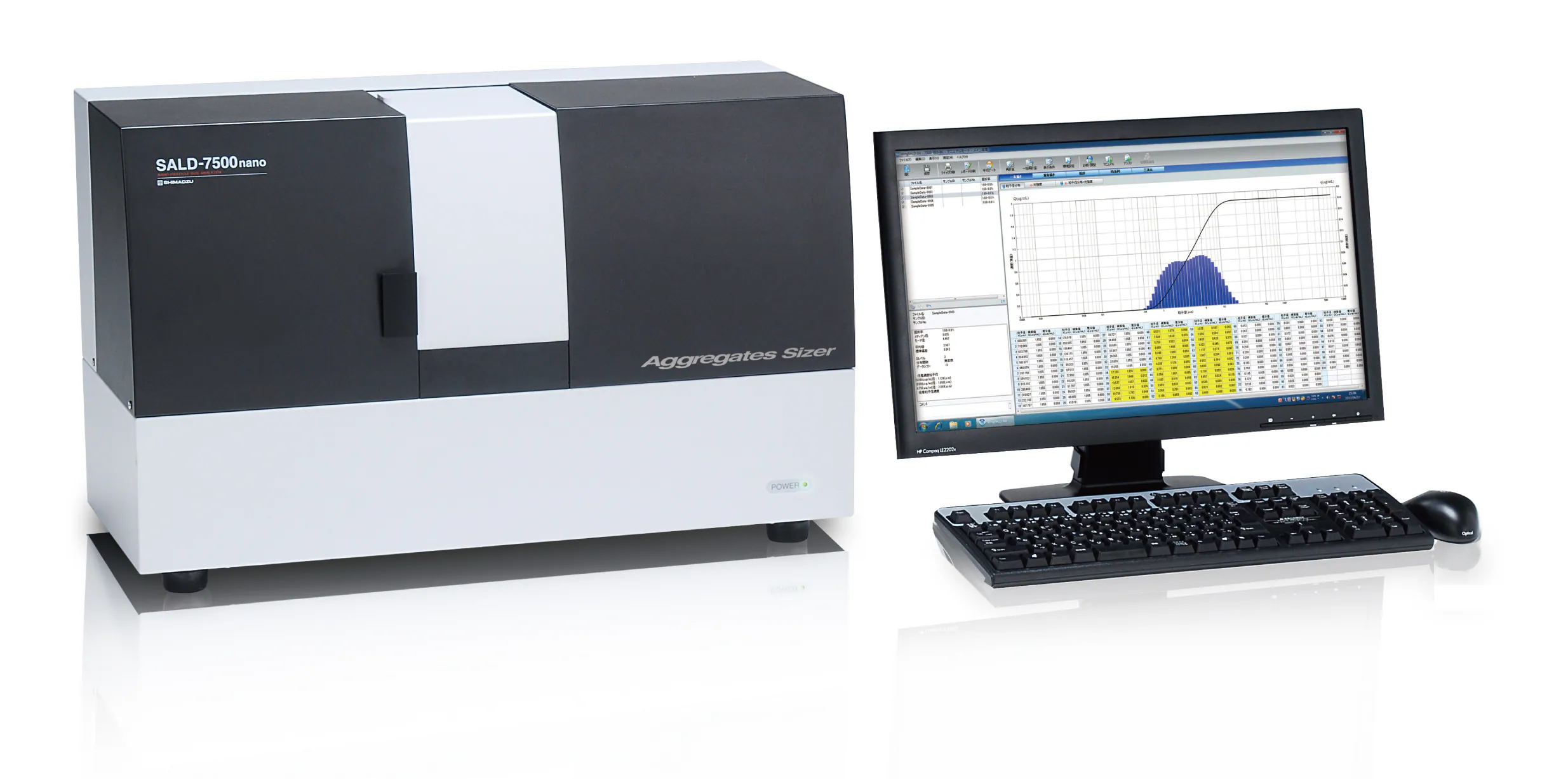

- Laser Diffraction: This technique involves passing a laser beam through a dispersed sample and measuring the diffraction pattern. The resulting data provide a comprehensive particle size distribution analysis.

- Dynamic Light Scattering (DLS): DLS measures the fluctuations in light scattering caused by the Brownian motion of particles. It is particularly useful for nanoparticles and provides information on their hydrodynamic size.

- Electron Microscopy: This advanced technique uses electron beams to visualize particles at an extremely high resolution, allowing for precise size measurement.

Significance in Industries:

- Pharmaceuticals: Particle size influences drug dissolution rates and bioavailability. Understanding the distribution ensures consistent drug performance and aids in formulation development.

- Paints and Coatings: Particle size affects the appearance, texture, and durability of coatings. Optimizing distribution enhances product quality and performance.

- Food and Beverages: In this industry, particle size impacts sensory attributes, texture, and stability of products. It is crucial for achieving desired product characteristics.

- Powders and Granules: Industries dealing with powders, such as in the production of ceramics or catalysts, rely on precise particle size distribution for optimal performance and efficiency.

Grasping the intricacies of particle size distribution is paramount for various industries. Accurate measurement techniques and an understanding of the significance of particle size in different applications empower scientists and engineers to tailor products for optimal performance, ensuring quality and compliance with industry standards. As technology continues to advance, so too will our ability to analyze and manipulate particle size distributions, driving innovation across diverse sectors.